Can plastic be used in place of corrugated metal sheeting?

At Liberty Plastics, our experts are here to guide you, so you can identify the best material for your component. In the meantime, use this overview of Wave-Core™ and how its properties stack up to metal sheeting.

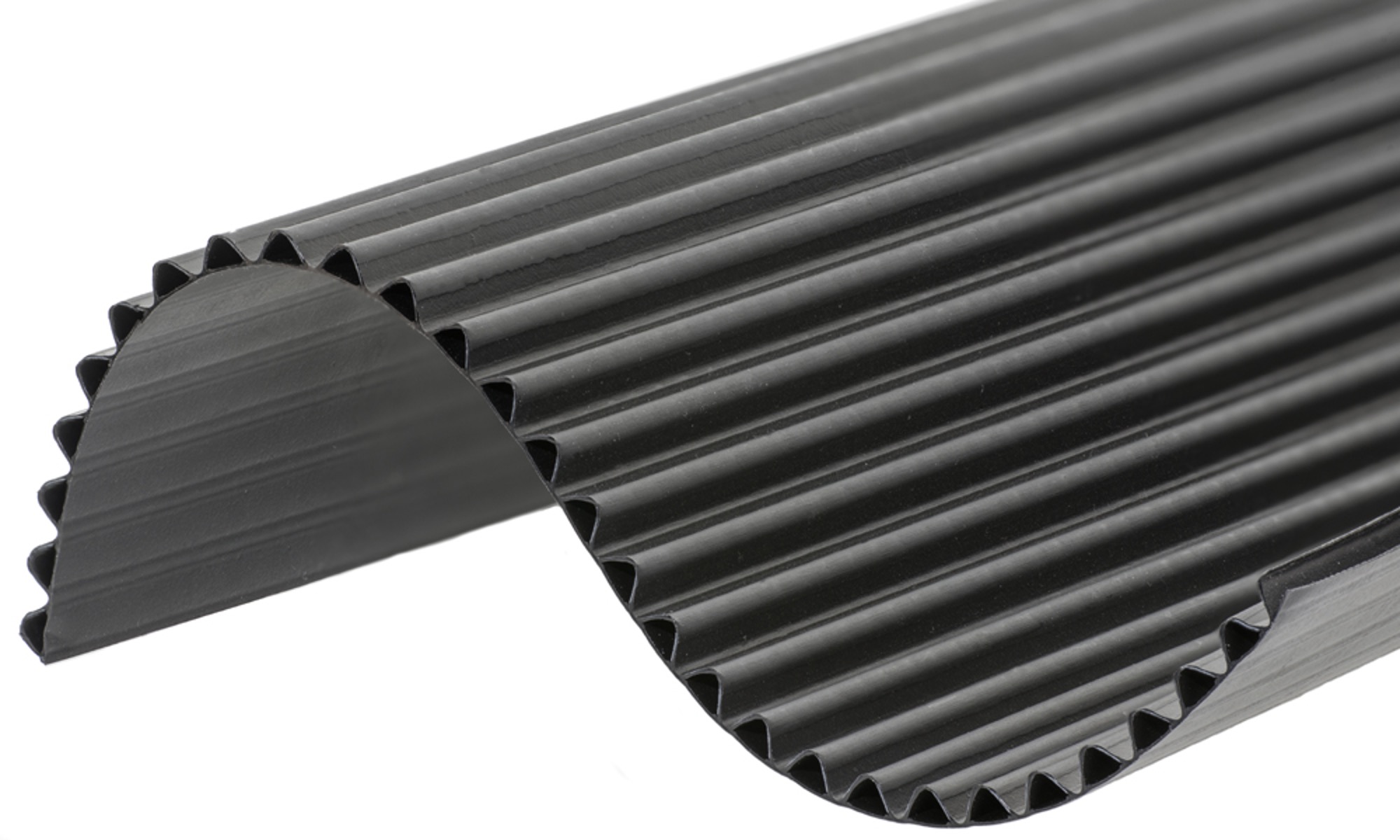

Understanding Wave-Core: The power and strength of HDPE plastic

Wave-Core is our flagship product here at Liberty Plastics. It’s made entirely of HDPE plastic, a polymer that boasts exceptionally high tensile strength and durability, which makes it a great candidate as a replacement for metal. The unique fluted core adds lightweight, structural strength.

Wave-Core is completely customizable. We can formulate it to create rigid sheets or flexible rolls, manufacture dual layers or triple layers, and die-cut it to meet your requirements.

Because HDPE is easily recyclable and widely accepted at U.S. recycling facilities, Wave-Core can help your company achieve its sustainability initiatives.

With Wave-Core’s applications across multiple industries, including construction and building, you can unlock new design solutions that enhance your products and service offerings.

How does corrugated HDPE outperform metal sheets?

Consider the properties and benefits of corrugated HDPE, and you may find that Wave-Core is the better option compared to metal sheeting.

Fabrication

HDPE can be die-cut to extremely tight tolerances, but its malleability makes it better suited than metal for fabricating intricate shapes.

Impact resistance

Wave-Core accepts screws, nails, staples, and other fasteners without breaking apart or splitting, properties that put it on par with metal.

Appearance

Wave-Core’s durable properties are what help it maintain its original appearance for years. Unlike metal, Wave-Core’s surfaces resist dings, dents and scuffs.. When folded or bent, it won’t craze or crack.

Color and logo

Apply paint or labels to metal, and they’ll eventually fade or flake off. Compared to metal surfaces, Wave-Core comes out ahead for displaying custom colors, logos and messaging — permanently, no need for paint or adhesive labels to achieve the color or look of your product. Before we manufacture it, we can blend the resins with your chosen pigment for a vibrant, color-fast result. Our printing and embossing capabilities keep your logo and graphics looking sharp for years.

With these options at your disposal, you can achieve more variety and customization from Wave-Core than with metal sheeting.

Chemical resistance

Wave-Core can stand up to a multitude of chemicals, some of which would cause corrosion in certain metals.

Climate resilience

Wave-Core’s performance holds up under long-term outdoor use. In addition to its ability to withstand hot and freezing temperatures without cracking, HDPE resists rust and can be formulated for UV resistance.

Lightweight

Wave-Core’s mass per square foot is a fraction of that of many sheet metals, which makes it cost-effective to ship, and lightens the load to whatever it’s applied to.

Workplace safety

Using Wave-Core can be advantageous for workplace safety because it is lightweight for ease of handling and transporting. With sheet metal’s hard, sharp edges, handling demands additional safety precautions to offset the risks.

Let us design your solution

Whether you're ready for a quote or researching your options, we're here to help. Contact us to learn more about our durable plastic solutions for construction and building with Wave-Core.

< GO BACK | NEXT POST >