Liberty Plastics Packaging Solution Protects Lumber During Transport

Project Overview

To keep lumber safe during transportation and storage, it’s essential to have a durable solution that can withstand various weather conditions. Liberty Plastics, Inc. created a packaging solution to protect lumber for a building materials distributor who needed to prevent damage and revenue loss while storing their wood products outdoors.

Challenge

Liberty Plastics needed to find a durable solution that could with-stand the transportation process and protect the lumber from moisture and frost damage upon arrival. Packaging needed to:

- Ship flat, easy-to-store and assemble

- Withstand cracking and splitting

- Sustain long-term outdoor conditions, rain, UV, wind, and cold

- Provide flexible and lightweight protection

- Reduce slippage from frost accumulation

Solution

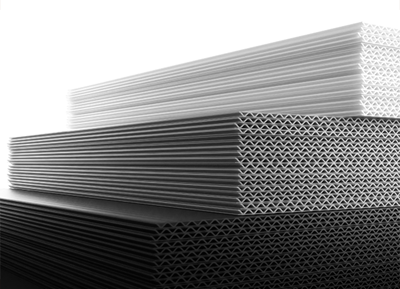

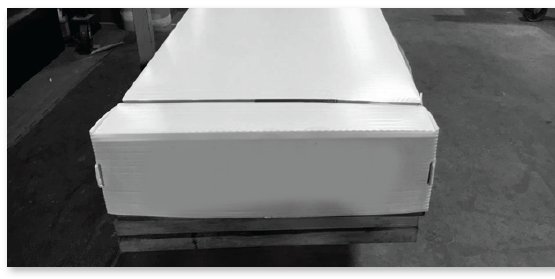

Liberty Plastics designed a proprietary solution that protected the wood from outdoor elements as well as the rough conditions of travel. Our team scored and notched corrugated plastic sheets—creating a protective layer to place over the wood, which folded along the sides and banded. Why our solution works:

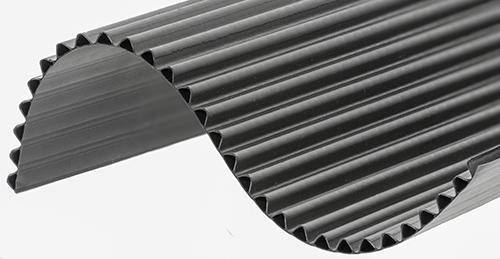

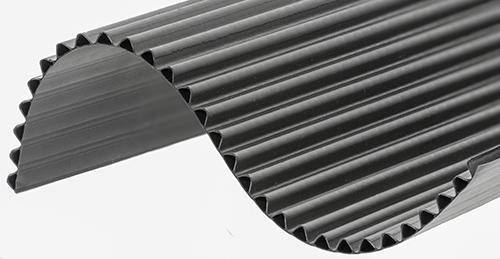

- HDPE corrugated material will not crack or split from banding or cold environments

- Lightweight, flat sheets are easy to handle

- Die-cut and scored makes for easy folding

- Anti-static treatment reduces slippage

- Can be stored outdoors for long periods

Services Provided

- HDPE corrugated plastic sheets

- Die-cut & scoring

- In-house design

- Anti-static additive

- 100% recyclable - No glues or staples

- 100% reusable packaging

Download Case Study