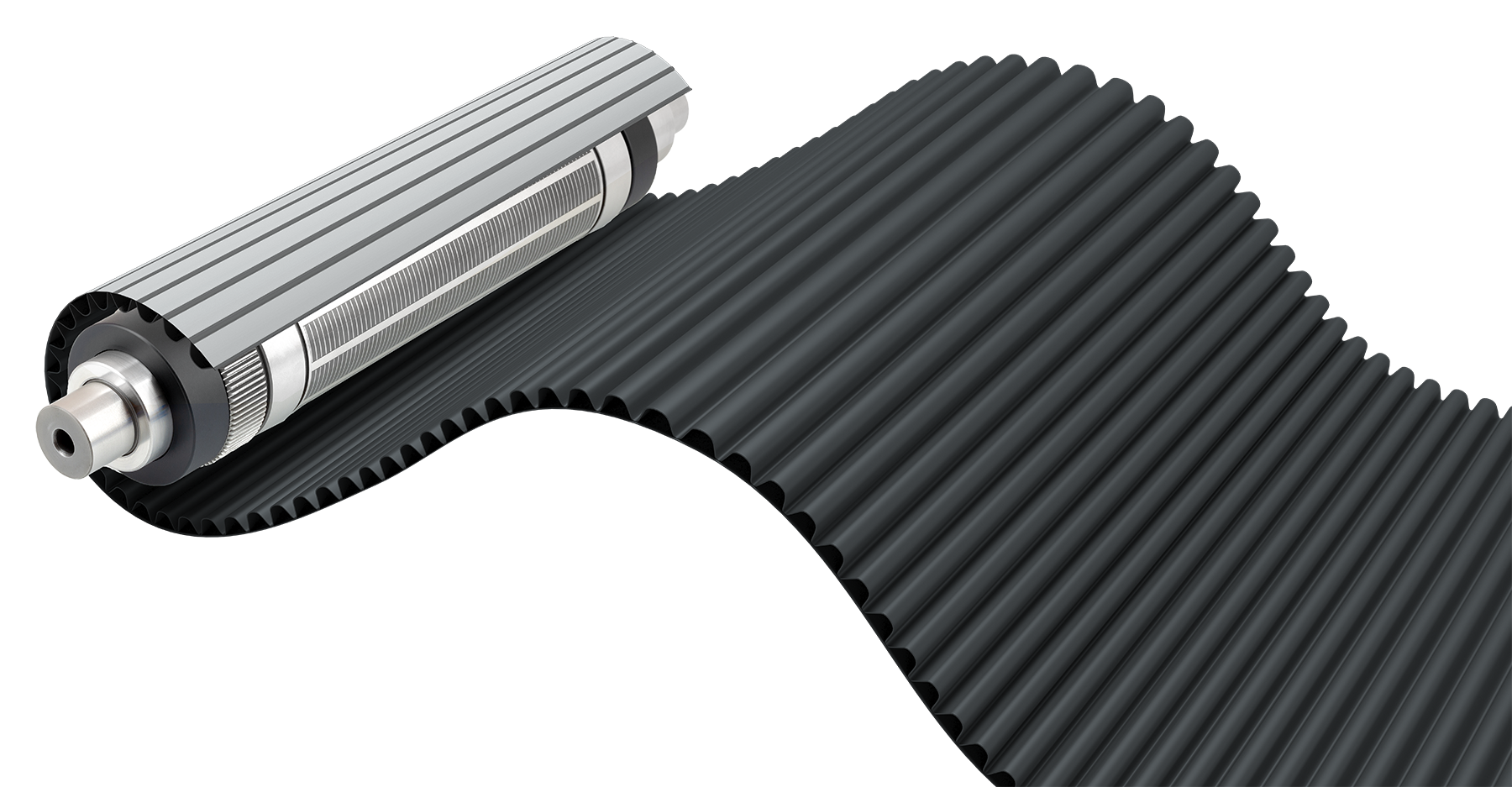

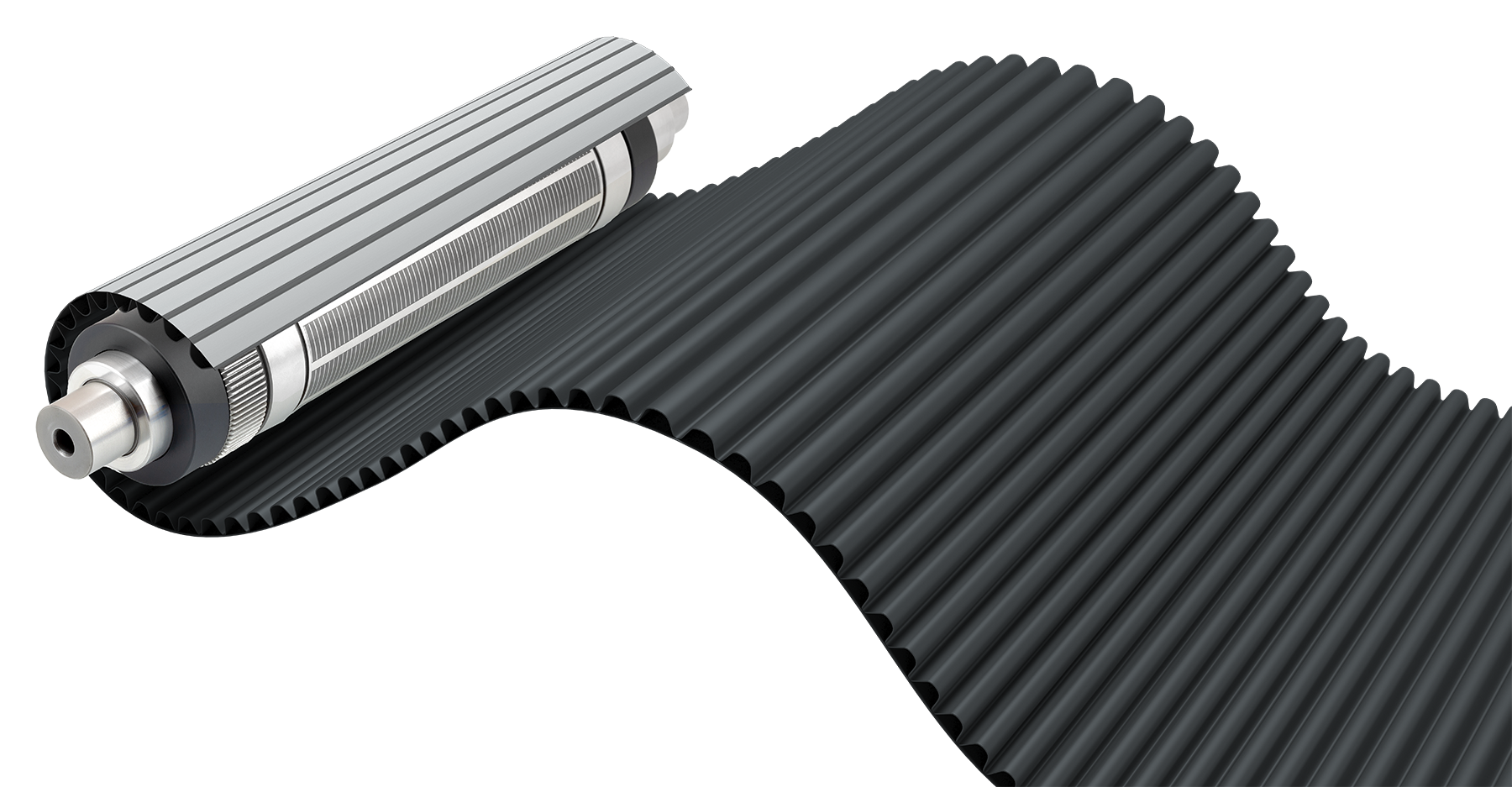

Wave-Core™ FLEX

DENSITY:

(g/m2): 535-730

TYPES:

Double-Layer Sheets & Rolls

USES:

Flexible packaging, surface protection, bulk packaging, flexible print media, laminations, underlayment, custom additives, FDA compliant, flame retardant.

DENSITY:

(g/m2): 535-730

TYPES:

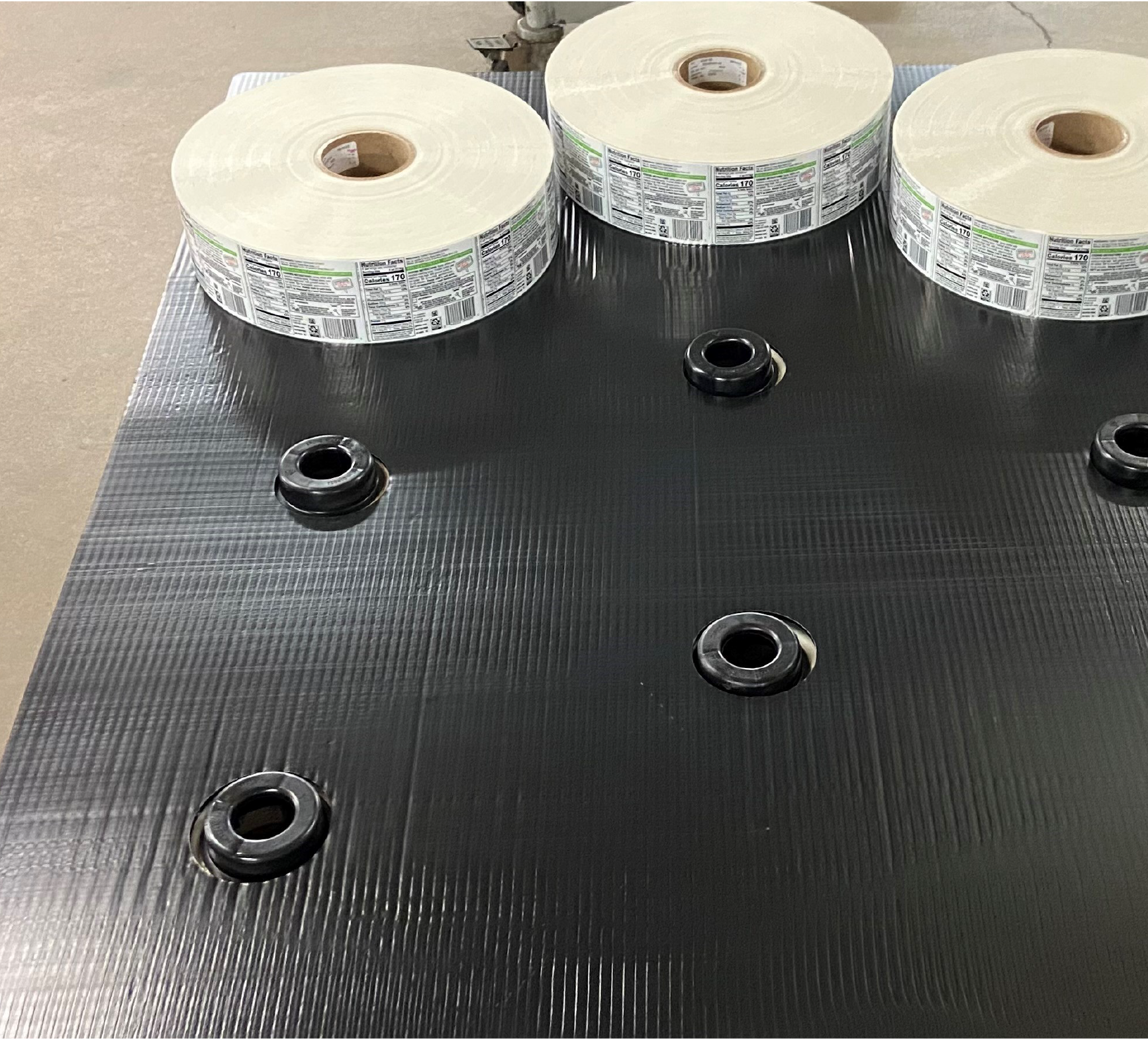

Double-Layer Sheets & Rolls

USES:

Flexible packaging, surface protection, bulk packaging, flexible print media, laminations, underlayment, custom additives, FDA compliant, flame retardant.

DENSITY:

(g/m2): 530-730

TYPES:

Double-Layer Sheets & Rolls

USES:

Flexible packaging, surface protection, bulk packaging, flexible print media, laminations, underlayment, custom additives, FDA compliant, flame retardant.

| CONSTRUCTION | DENSITY | SHEETS | ROLLS | USE CASE EXAMPLES |

|---|---|---|---|---|

| Double-Layer | 535 g/m2 |  |

|

Protective wrap for piping and pipe edges. Protection for high-value film and fibers. Separation/Dunnage for food and produce. |

| Double-Layer | 680 g/m2 |  |

|

Dividers, boxes, and slip sheets for manufacturing needs. |

| Double-Layer | 730 g/m2 |  |

|

Internal and external protection for trailers and recreation vehicles. Temporary construction flooring protection. Slip sheeting for food conveyance. |

CONSTRUCTION

Double-Layer

DENSITY

535 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Protective wrap for piping and pipe edges.

Protection for high-value film and fibers.

Separation/Dunnage for food and produce.

CONSTRUCTION

Double-Layer

DENSITY

680 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Dividers, boxes, and slip sheets for manufacturing needs.

CONSTRUCTION

Double-Layer

DENSITY

730 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Internal and external protection for trailers and recreation vehicles.

Temporary construction flooring protection.

Slip sheeting for food conveyance.

DENSITY:

(g/m2): 780-1070

TYPES:

Triple-Layer Sheets & Rolls

USES:

High-value packaging, internal components, reusable/returnable packaging, print media & graphics, point-of-purchase displays, large sheeting needs, totes, boxes, bins, custom additives, FDA compliant, flame retardant.

DENSITY:

(g/m2): 780-1070

TYPES:

Triple-Layer Sheets & Rolls

USES:

High-value packaging, internal components, reusable/returnable packaging, print media & graphics, point-of-purchase displays, large sheeting needs, totes, boxes, bins, custom additives, FDA compliant, flame retardant.

| CONSTRUCTION | DENSITY | SHEETS | ROLLS | USE CASE EXAMPLES |

|---|---|---|---|---|

| Triple-Layer | 780 g/m2 |  |

|

Variety of packaging applications: boxes bins and totes. Protection in contruction projects. Foot transportation and handling. |

| Triple-Layer | 975 g/m2 |  |

|

Protection for landscaping stones, singage and printing applications Sheet used for component FR parts. Protection for biological products. |

| Triple-Layer | 1070 g/m2 |  |

|

Sheet protection for large printing rolls. Sheet protection for industrial equipment. Sheet protection for die-cutting parts. |

CONSTRUCTION

Triple-Layer

DENSITY

780 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

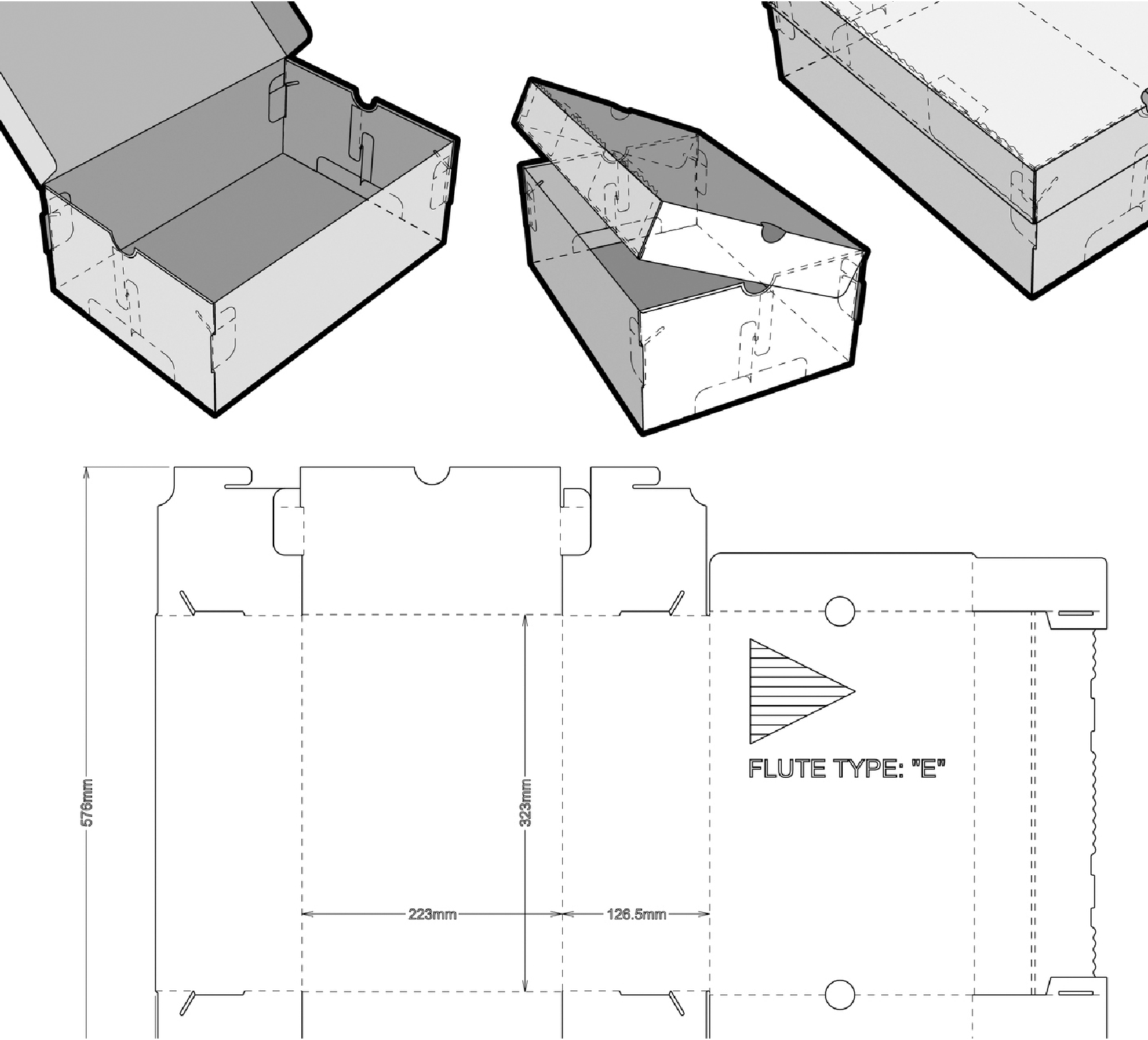

Variety of packaging applications: boxes bins and totes.

Protection in contruction projects.

Foot transportation and handling.

CONSTRUCTION

Triple-Layer

DENSITY

975 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

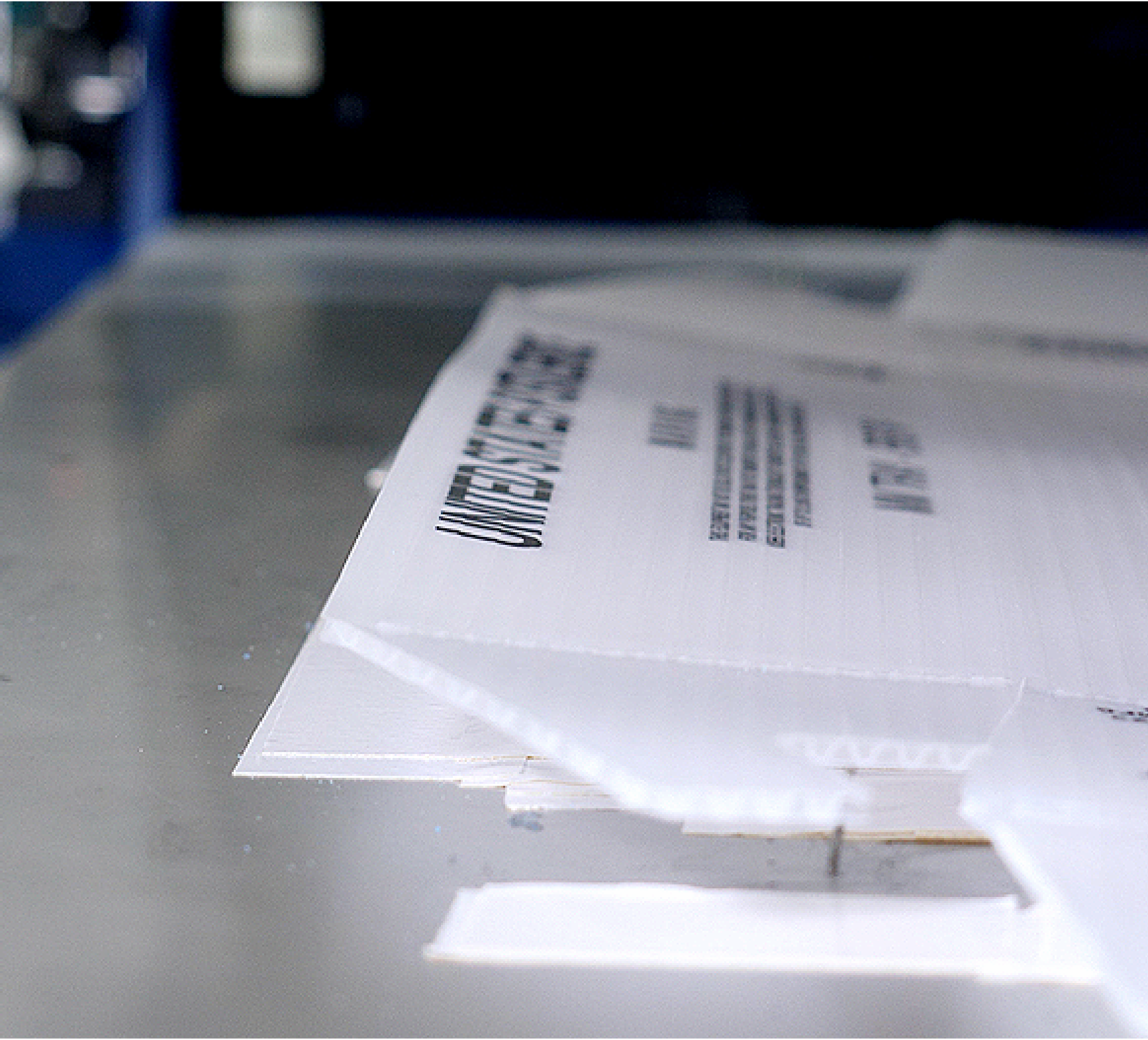

Protection for landscaping stones, singage and printing applications

Sheet used for component FR parts.

Protection for biological products.

CONSTRUCTION

Triple-Layer

DENSITY

1070 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

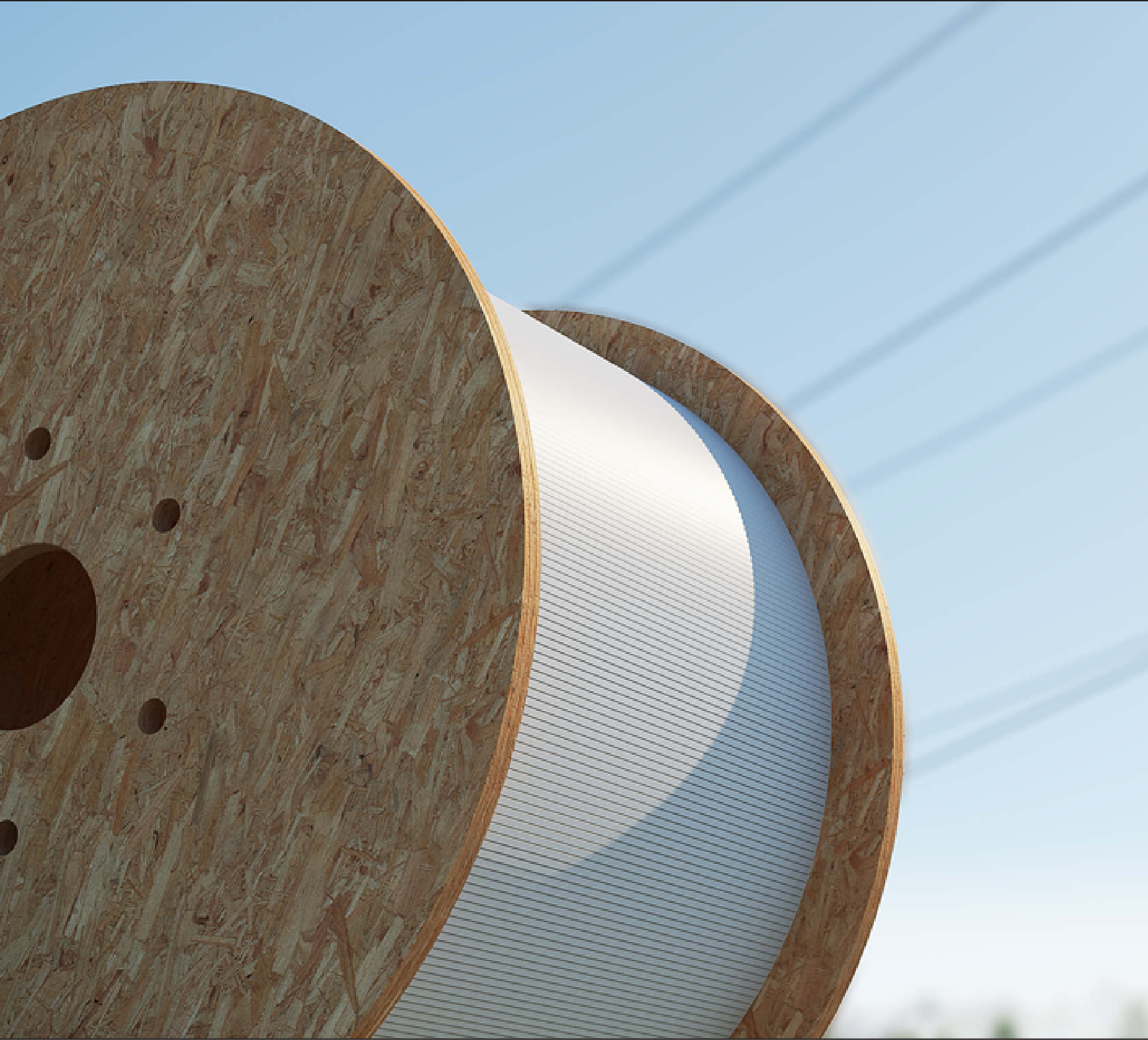

Sheet protection for large printing rolls.

Sheet protection for industrial equipment.

Sheet protection for die-cutting parts.

DENSITY:

(g/m2): 1460-2440

TYPES:

Triple-Layer Sheets

USES:

Packaging reinforcement, partitions and dividers, paneling, slip sheets, engineered parts, laminations, custom additives, FDA compliant, flame retardant.

DENSITY:

(g/m2): 1460-2440

TYPES:

Triple-Layer Sheets

USES:

Packaging reinforcement, partitions and dividers, paneling, slip sheets, engineered parts, laminations, custom additives, FDA compliant, flame retardant.

| CONSTRUCTION | DENSITY | SHEETS | ROLLS | USE CASE EXAMPLES |

|---|---|---|---|---|

| Triple-Layer | 1460 g/m2 |  |

Die-cut component parts. Commercial component applications. Protection and transport for food and beverage. |

|

| Triple-Layer | 1950 g/m2 |  |

Protection for landscaping stones. Sheet protection for high-value machinery. Protection for biological products. |

|

| Triple-Layer | 2440 g/m2 |  |

Heavy-duty protection for product handling. Heavy-duty protection for industrial equipment. Material handling protection in food and beverage distribution. |

CONSTRUCTION

Triple-Layer

DENSITY

1460 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Die-cut component parts.

Commercial component applications.

Protection and transport for food and beverage.

CONSTRUCTION

Triple-Layer

DENSITY

1950 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Protection for landscaping stones.

Sheet protection for high-value machinery.

Protection for biological products.

CONSTRUCTION

Triple-Layer

DENSITY

2240 g/m2

SHEETS

ROLLS

USES CASE EXAMPLES

Heavy-duty protection for product handling.

Heavy-duty protection for industrial equipment.

Material handling protection in food and beverage distribution.