Wave-Core™ Prevents Damage and Cuts Costs For Stone Manufacturer

Project Overview

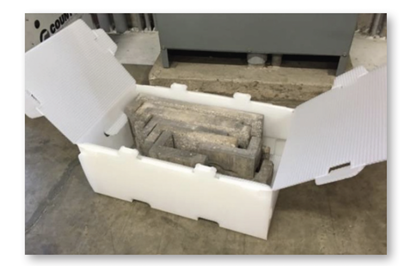

A leading stone manufacturer needed an efficiently-designed packaging solution that would prevent stone damage and promote employee safety during shipping, handling, and storage. They turned to the Liberty Plastics, Inc. product design team—we identified pain points in their current packaging product and created a new, high-quality solution that enhanced delivery satisfaction, brand reputation, and company revenue.

Challenge

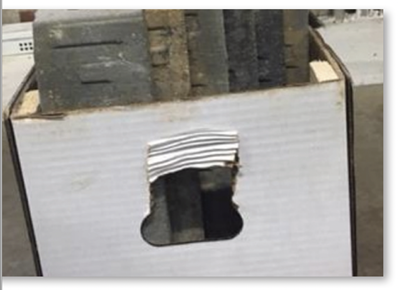

The manufacturer’s lengthy assembly process needed an overhaul. Prior to our partnership, their approach included top and bottom assembly, wood cutting for support posts, and adding extra support due to the weight. The boxes were then stored in a cold, damp environment, which caused them to break in transit—damaging the stone product.

The manufacturer needed a solution that could:

- Reduce labor costs and assembly time

- Support the product’s weight

- Sustain outdoor weather conditions, including rain, snow, and cold

Solution

The Liberty Plastics team designed and delivered an efficient packaging solution with die-cut handles and built-in top flaps that would fold and stack effortlessly. The boxes are reusable, which lowers costs and environmental impact.

The Liberty Plastics design team:

- Created a one-piece, one-step design to reduce assembly time

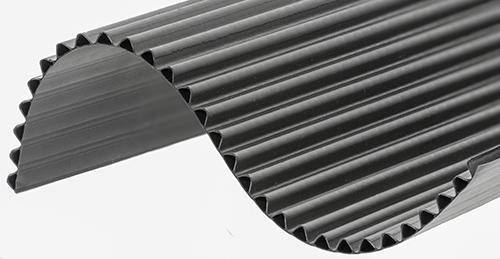

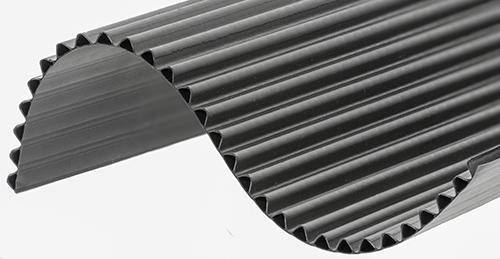

- Used HDPE corrugated material, which withstands cold and wet environments

- Eliminated product damage during transit with a rigid, supportive design

Services Provided

- In-house custom design capabilites

- Stackable design

- Die-cut & scoring

- Handles

- Logo printing

- HDPE corrugated material

- 100% recyclable - No glues or staples

- 100% reusable packaging

Download Case Study