Wave-Core™ liners create huge savings for print press rollers

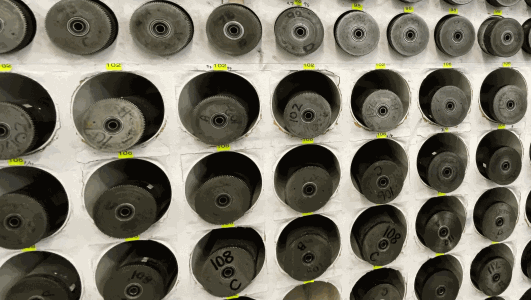

A leading Midwest label and packaging company was having issues protecting their rollers and rotary tooling equipment from costly damage. Liberty Plastics was called in to identify and create a solution to protect the products.

Challenge

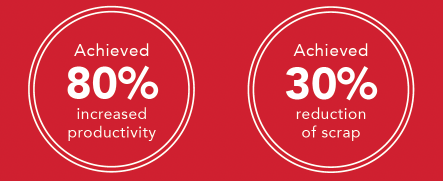

The surfaces of the company’s rollers and rotary tools are extremely delicate and any physical damage would cause:

- Poor or non-conforming print quality

- Increased inspection time on finished products

- Costly need for rework and reruns

- Increased setup and adjustment time

- Decreased productivity

Solution

Solution

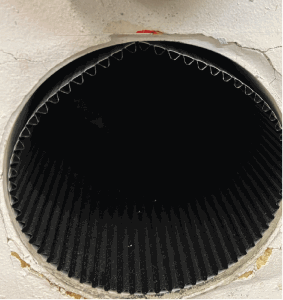

The team at Liberty Plastics partnered with the client to come up with a solution using our 110# Wave-Core™ Single-Face corrugated plastic. The Wave-Core™ plastic would be used as a liner within each individual roller storage tube to protect and eliminate the damage of the rollers as they are take in and out for use in the presses. The durable, protective liner can easily be cleaned and replaced as needed extending the usable life of the rollers and rotary tooling, and saves the client thousands of dollars in early replacement costs.

Services Provided:

- Multiple discovery meetings and onsite visits

- In-house design and prototype development

- Onsite prototype installation

Custom Capabilities:

- Die-Cutting

- Sonic Welding

- Fasteners & Wire Reinforcement

- Printing & Embossing

- Non-skid Coating

- Color & Logo Customization

- Prototype Design & Fabrication

Download Case Study