Can plastic be both flexible and strong? Absolutely! A common misconception about plastic is that you must choose one quality at the expense of the other. With Wave-CoreTM Flex by Liberty Plastics, that’s no longer the case. Made from durable HDPE plastic designed to flex and roll, Wave-Core Flex offers a robust yet flexible solution for a variety of applications.

To help you explore the potential this material offers for your operations, this blog highlights its features, benefits, and examples of practical applications. When you're ready to move forward, reach out to our experts to learn more.

Flexible plastic solutions for industrial applications

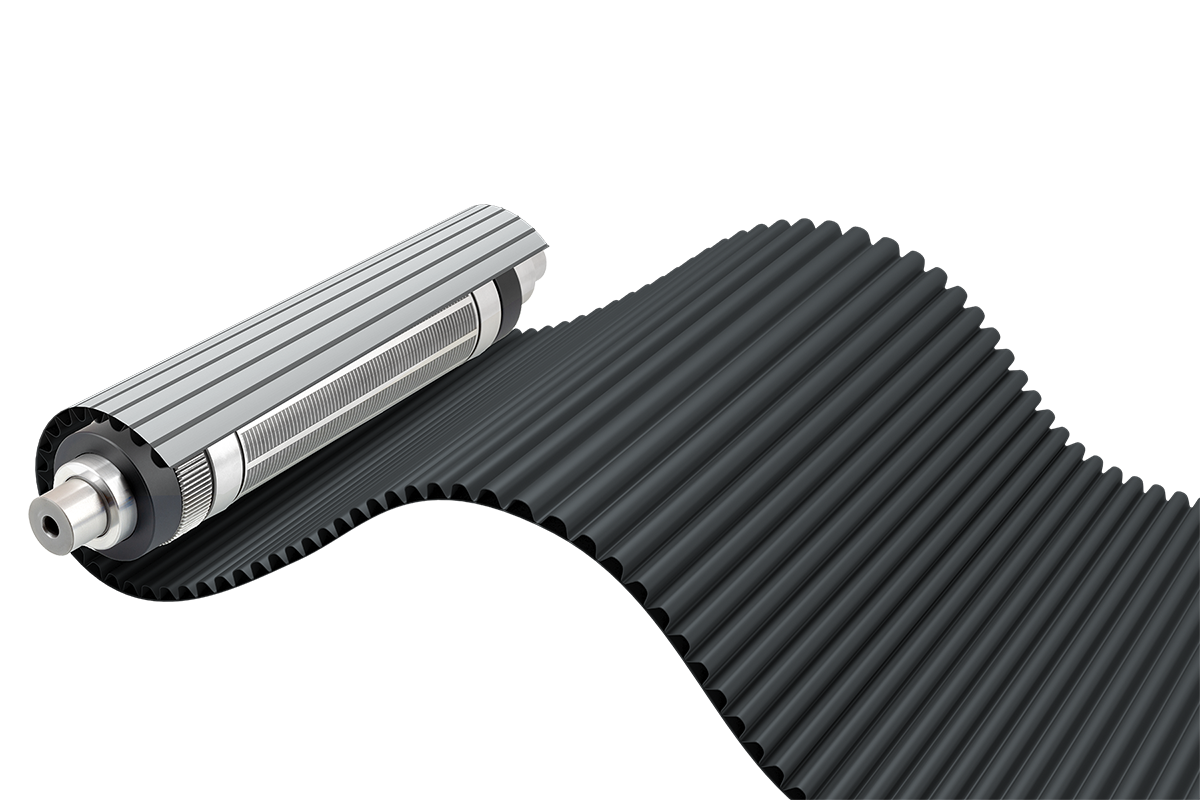

Flexibility is essential in manufacturing and industrial settings. Wave-CoreTM Flex provides a versatile solution with its ability to warp and roll, making it adaptable to unique designs while also standing up to challenging environments. Wave-CoreTM comes with high tensile strength, enabling it to resist tears, punctures and breaks, outmatching cardboard and shink warp. At the same time, it also resists moisture, heat and chemicals, and can be easily cleaned and reused.

In situations where you’re dealing with large, rigid, bulky or expensive components, Wave-CoreTM Flex provides protection and cushioning. Its corrugated HDPE construction offers a rare combination of strength and flexibility.

Wave-CoreTM Flex: The key features

What gives Wave-CoreTM Flex its durable properties while still allowing it to flex and roll? The secret lies in its molecular makeup and structural composition. Made from HDPE plastic, Wave-CoreTM Flex benefits from the dense chains of polymers that make it highly resistant to tears and punctures. Its two-layer construction features a wave-like core, which enhances structural strength while providing additional cushioning against impacts. To achieve its unique flexibility, we use a specialized formulation of the HDPE resins.

Customizable

Versatility is a hallmark of Wave-CoreTM Flex. It can be cut to the exact dimensions of your application, whether in-house or through our fabrication services, ensuring a flexible and protective solution made to fit your needs. For further customization, all Wave-CoreTM products can be designed to match your color specifications or screen-printed to bear your logo or message.

Resistance to moisture and chemicals

Wave-CoreTM Flex is highly resistant to both moisture and chemicals, making it ideal for indoor and outdoor applications. Whether used as a sheath for raw materials, a reinforced liner or a functional component, its surface is easy to clean and sanitize, offering a durable long term solution that withstands demanding environments.

Top applications of Wave-CoreTM Flex

Wave-Core Flex boasts a unique combination of strength, thinness and flexibility. From this many possible applications can unroll.. Here are some of the problems solved by Wave-CoreTM Flex, which can inspire new possibilities for your operation.

Packaging

For spool shipments and shipping bulk items, Wave-CoreTM Flex provides a snug yet reusable wrap. Not only can it be custom-cut to fit the dimensions of your freight, but we can also add metal fasteners for added security. Its cushioning and impact-deflecting properties protect contents from the rough handling and shifting that can occur during transit, helping your shipments arrive intact. Less damage means happier customers, less repacking and reverse logistics and less rework -- all of which save your customer time and money.

Read our case study: Wave-Core Flex Prevents Damage During International Transportation.

Tip: Make a stronger impression by having us screen print your logo directly onto the Wave-Core wrap.

Construction

Wave-CoreTM Flex offers many uses as a temporary barrier, panel or covering during construction and remodeling projects. Unroll for temporary flooring, or as a flexible shield against overspray or to protect materials from exposure to rain or frost. For a secure fit, it can takes nails, screws and other metal fasteners without cracking or splitting. Once the job is complete, give it a quick cleanup and it’s ready for reuse at the next project.

Design your own solution

Whatever your industry, Wave-CoreTM Flex can be customized to meet your unique needs, whether you need a barrier, a cushioning material or a protective wrap. Its versatility allows it to function as protective sleeves, reinforced liners or flexible wraps and. Wherever curved or flexible surfaces require snug cushioning or reliable shielding, let Wave-CoreTM Flex provide your solution.

Let us design your flexible solution

Ready to see the difference Wave-Core™ Flex can make for your business? Request a sample today or contact the experts at Liberty Plastics for tailored recommendations. Discover how Wave-Core™ Flex can provide innovative solutions for your application. Contact us today to discuss your industrial or packaging needs.