Wave-Core™, exceeding expectations for quality bulk pack shipping.

Project Overview

Viking Label and Packaging, a custom label converter based in Minnesota, partnered with Liberty Plastics, Inc. during the COVID-19 pandemic when supply chain issues threatened their production abilities. Liberty Plastics helped Viking Label and Packaging avoid industry bottlenecks—and successfully serve their partners—by implementing a new product using Wave-Core™ technology.

Challenge

When the nationwide supply chain crashed due to the COVID-19 pandemic, Viking Label and Packaging felt its effects—impacting everything from carton box availability

to the shipment of finished labels. Without these labels, food processing plants would be forced to halt production, which would be detrimental to the dinner tables of millions of American families.

Solution

Solution

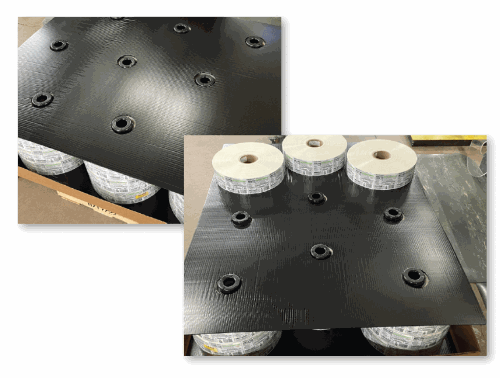

Liberty Plastics, Inc., swiftly stepped in to create a “Bulk Pack” using Wave-Core™ corrugated plastic. This implementati on helped Viking Label and Packaging avoid a potential supply disruption and continue providing high-quality service to their clients.

on helped Viking Label and Packaging avoid a potential supply disruption and continue providing high-quality service to their clients.

Impact

Beyond successfully avoiding production issues amid the pandemic, the “Bulk Pack” brought other benefits to Viking LP’s operations and customers that exceed expectations:

- Saving time and labor to tape, pack, seal, and load 54 carton boxes onto each pallet, which helped reduce overall manufacturing cost.

- Saving time in queuing the job from each station (label slitting to box packing to pallet packing), which helped increase operation efficiencies.

- Avoiding potential quality issues by eliminating a few “touch points” where operators must handle finished label reels by hand.

- Reusing of Wave-Core™ “weight distributing” interleaf boards, which helps reduce on-going cost of packing materials as well as reduce carbon footprint.

Download Case Study